Manufacturing Trends to Watch for in 2020

Over the past decade, the world has witnessed several technological advancements and improvements across industries. Such developments are a direct result of years of innovation and focused efforts by visionaries around the world. With the 4th Industrial Revolution, coded Industry 4.0, smart manufacturing is the buzzword in the manufacturing sector. The article will take us through the critical trends that are likely to impact the manufacturing industry in 2020. You may check also here – https://www.aem.org/news/5-manufacturing-trends-to-watch-in-2020/ – to know more about the manufacturing trends to watch out.

Top Industrial Trends for the New Decade

With the entire world going digital, the manufacturing sector can’t be left behind. Industry leaders are keeping a close watch on the new trends to leverage digital technology and maximize returns.

Some of the trends that cannot be missed are as below :

Internet of Things – IoT is a revolutionizing technology across industries. In the manufacturing sector, IoT enables the transformation of processes and the evolution of materials and production chain. Manufacturers can deploy IoT sensors in industrial equipment to trigger condition-based maintenance alerts. Cloud computing enables even smaller enterprises to take advantage of technology. ‘Internet of Goods’ is a new trend leading to the digitization of distribution, with manufacturers moving from warehouse model to flexible distribution options.

Artificial Intelligence – Technological innovation has powered automated process management and plays a significant role in the control and monitoring of machines. Artificial Intelligence and Machine Learning are the two key technologies that are enabling intelligent manufacturing. AI-powered Cobots are used to automate industrial operations, making human intelligence redundant for repetitive and systematic operations. The advent of Cobots and other task automation tools have significantly reduced the effort on time-consuming jobs.

5G Technology – The fifth-generation technology is anticipated to be a path-breaking innovation in the field of technology. Most developed countries have adopted 4G networks, and 3G is still in place in some developing nations. These technologies, though sufficient, are not reliable for large-scale operations. 5G promises advanced connectivity and bandwidth with minimum latency. This means, manufacturers will benefit from faster connections, as they embark on a centralized tracking, Cloud, etc. With superior coverage and stable connectivity, the result can be a smarter manufacturing ecosystem.

Predictive and Preventive Maintenance – With innovation in technology, the advent of IoT, better and stable connectivity, the future promises advanced modes of equipment monitoring using performance metrics and analytics. Manufacturers can have a better idea of system performance and can preempt any failures or breakdowns. They also get notified of the best times to carry out maintenance activities. Nanobots can be fitted in equipment, and these detect possible malfunctions, even before they occur. What used to be mere science fiction has become a reality, thanks to monumental advancements in nanotechnology.

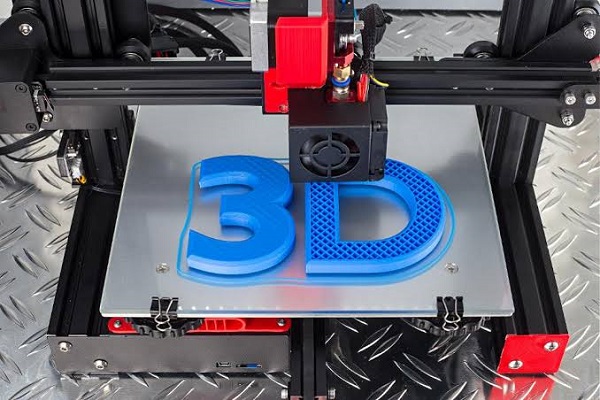

3D Printing – This is yet another path-breaking innovation that is truly transformational. 3D printing enables manufacturers to create product prototypes much faster. This is also a cost-effective option for product-designer to test and resolve issues before production. It also provides manufacturers the facility to produce only on-demand, reducing warehousing costs. 3D printing is already trending in the aerospace and automobile industries, and the other sectors are expected to catch up anytime soon.

Global Workforce/Extended Reality – The manufacturing industry is often plagued with a shortage of skilled workers. With advancements in internet technology and manufacturing systems going digital, the availability of STEM workers for manufacturing jobs is becoming more challenging. This is where extended reality offers to be a solution. Extended reality is the convergence of real and virtual environments. Manufacturers are already exploiting computer-generated environments and visual and audio aids to their benefit. The next decade may see extended reality become more real, with skilled workers across the globe operating and maintaining equipment anywhere in the world through XR sensors.

The Path Forward

Industries across the world are going through a digital transformation and reaping the benefits of the same. In this context, the above trends are hard to miss. Industry leaders should upgrade their systems and resources so that they could catch up with the trends. It is also essential to invest in reskilling/upskilling the workers on the new technologies so that they are ready to take on the challenges on the face. Challenging as it may sound, embracing new technologies with open arms is crucial for survival in this ever-changing competitive global market.